Industrial Leases: Creating Value through Operations Improvement

A company that leases an industrial space must answer three fundamental questions to maximize the return on their facility lease:

- How do you scale and grow with the real estate you have?

- How do you get the most out of your existing operations

- How do you negotiate and leverage the best real estate deal?

In short, the creation of leverage and cost savings in a real estate transaction is magnified when industrial users first address operations improvement.

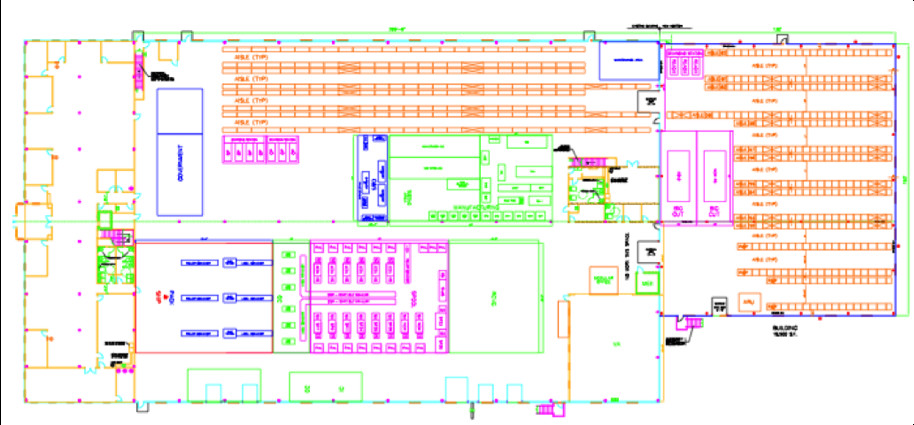

In a world of rising real estate costs, one of the first areas a company should focus on is optimizing inventory. One way to do this is inventory rationalization. How are your SKU’s racked? Are barcode systems in place? If SKU’s are segregated by weight & size (instead of by customer) into different areas in your racking configuration, denser racking & narrower aisles can be achieved for smaller and/or lighter pallets.This will cut down on required square footage or create areas to expand value added manufacturing floor space.

Further, narrower aisles can be achieved by optimizing your material handling equipment, installing wire-guided systems, or deep-reach racking systems.

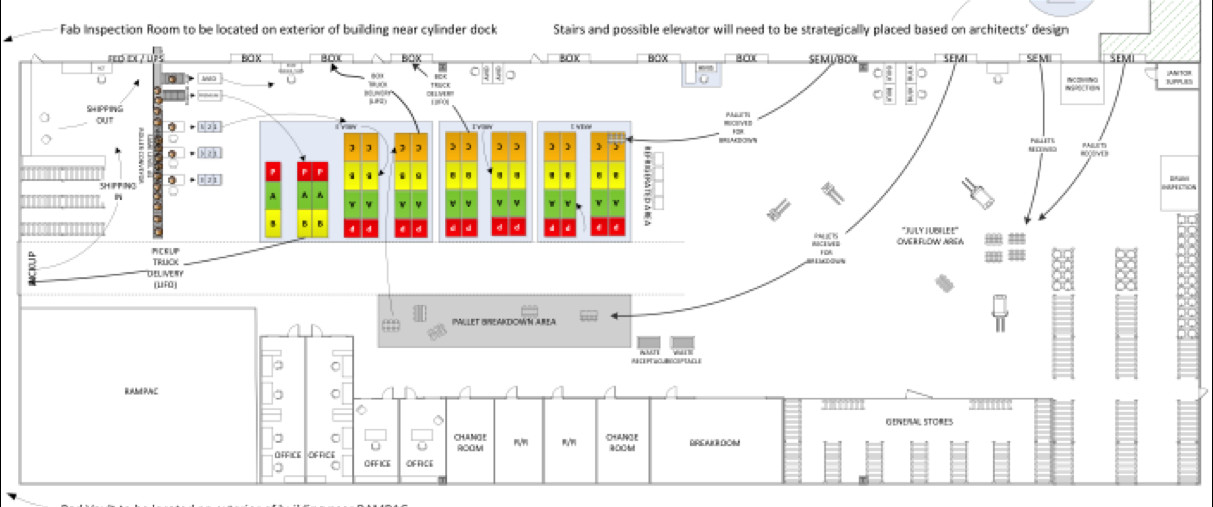

The next area within a warehouse operation that can be optimized to improve the return on leased space is flow and throughput.

The first step involves taking a close look at the physical constraints of your building: Is the building cross-docked or do you have doors along one side of the building? What is the velocity of materials through the warehouse? How often are they touched? The best way to deal with optimizing throughput is to create a value-stream map. This will help you determine which areas in the material flow are ‘value add’ and ‘non-value add’. You will then be able to identify steps that can be terminated or enhanced. Further, throughput can be improved by providing warehouse workers with visual tools & metrics.

This will speed up task identification, prioritization, locating SKU’s and provide a framework for a team to understand and meet daily goals. Remember, it is very important this tool is geared toward workers continuous improvement vs. a management tool to scrutinize performance.

Only after an operation is optimized in whole or in part, should scaling and replication be addressed. Areas of waste and inefficiency are only magnified and can create costly mistakes, one being lease commitments on space that is simply too large.

By addressing areas like inventory segregation and value-stream mapping, companies can literally create opportunities and leverage when it comes to real estate transactions. Further, this will streamline growth and ability to enter new markets through replication of processes. Most brokerage firms only attempt to answer #3 (Let’s make a deal!) At Cresa, we combine ‘Best in Class’ consultants from Industry and expert Advisory Services. Our aim is to truly represent tenants and their operational objectives. With a team of seasoned consultants that have ‘walked the walk’ across industry combined with expert brokerage advisory, we formulate ongoing real estate strategies that facilitate your business operations and enhance profitability.